Offering levels

Refurbishment

- Clean and ensure the functionality of the machine

- Cost-efficient way to pro-long your TANA machine’s life-time

Rebuild

- Restore the machine performance to it’s original level

- Sustainable approach to provide second-life for the equipment

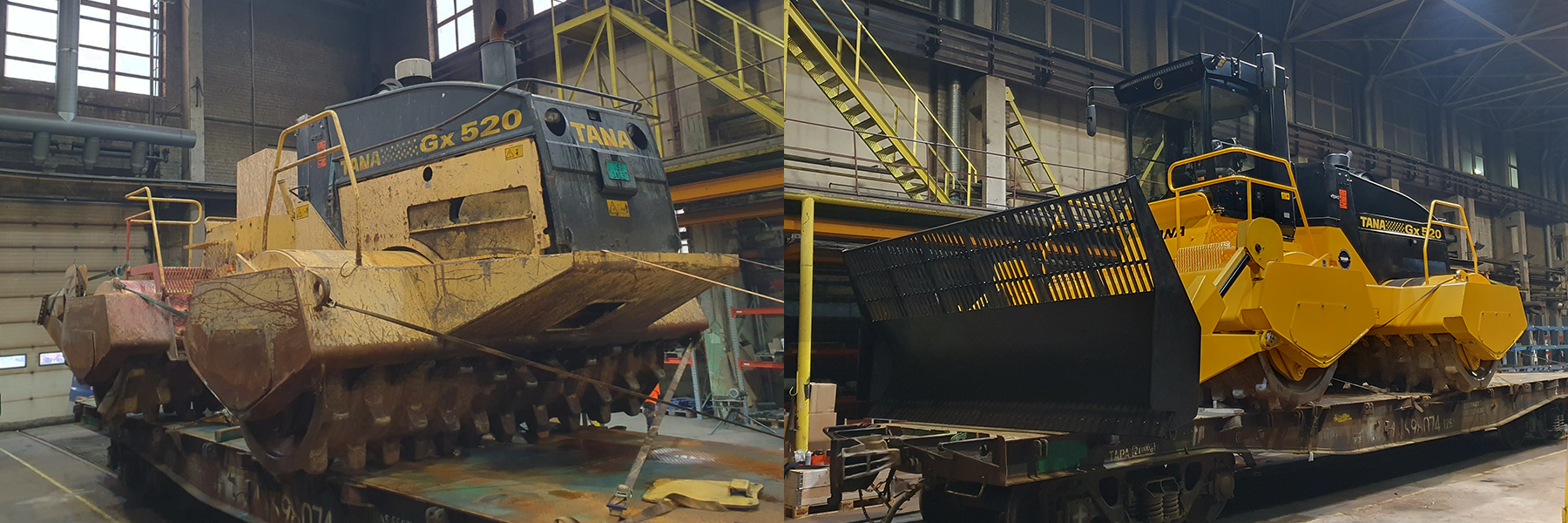

REBUILD PROJECT

| 1. Disassembly | The equipment undergoes a systematic disassembly process, with necessary components removed for detailed inspection and refurbishment. |

| 2. Repair and replacement | Worn or damaged components are repaired or replaced with either new or refurbished parts. This process extends to critical systems such as the engine, transmission, hydraulics, and undercarriage. |

| 3. Overhaul | Major systems, including the engine and transmission, may undergo a comprehensive overhaul to restore them to a like-new condition. This involves rebuilding engines or replacing significant components such as pistons, bearings, and seals. |

| Cleaning and painting | The equipment is thoroughly cleaned and, if necessary, repainted to safeguard against corrosion and enhance its visual appearance. |

| 5. Testing and Quality Control | Following reassembly, the equipment undergoes stringent testing to ensure optimal functionality and safety. This includes comprehensive functional testing of all systems, coupled with safety inspections. |

| 6. Reassembly | The equipment is reassembled, incorporating the refurbished or replaced components. |

| 7. Final Inspection | A final inspection is conducted to verify that the equipment meets all safety and performance standards, ensuring compliance with rigorous quality criteria. |

| 8. Documentation | Detailed records of the entire rebuild process are maintained for reference and future maintenance purposes, providing a comprehensive overview of the undertaken activities. |